如何测量验收环氧防静电地坪?防静电地坪验收测量前,应用洁净的纱布将环氧树脂地坪表面擦干净,严重玷污的应用中性液清洗干净。然后将室内空调打开,保持一定温度连续开上23天,规定的温湿度条件下测量。放置电极前先用软布条插去地表面所有尘物,电极表面在放置前要用干净的软布条粘上异丙醇不少于70水插试干净,22面积,至少做5次测试.5次测试中少3次的测试应当包括受磨损的有化学品或水溅落的有明显沾污的区域。

How to measure and accept the epoxy anti-static floor? Before acceptance of the anti-static floor, clean the surface of the epoxy resin floor with clean gauze, and clean the application neutral liquid which is seriously polluted. Then turn on the indoor air conditioning, keep a certain temperature for 23 days, and measure under the specified temperature and humidity conditions. Before placing the electrode, insert all dust on the surface with a soft cloth strip. Before placing the electrode surface, stick isopropanol with a clean soft cloth strip at least 70 water plugs to test clean, 22 areas, and at least 5 tests. Less than 3 tests in 5 tests should include worn areas with obvious contamination caused by chemicals or splashed water.

环氧防静电地坪优势:

Epoxy anti-static floor advantages:

对于环氧防静电环氧地坪来说,首先要考虑到环氧地坪涂层的防静电指标;

For the epoxy anti-static floor, the anti-static index of the epoxy floor coating should be considered first.

其次还有环氧地坪涂层的抗压强度、抗拉强度和耐磨性,以及通常的耐化学品性能。

Secondly, there are the compressive strength, tensile strength and wear resistance of epoxy floor coating, as well as the usual chemical resistance.

所以在设计防静电环氧地坪漆配方时基本上选用环氧树脂作为基料,添加导电物质、填料、溶剂及助剂,制成环氧防静电地坪漆涂料。

Therefore, epoxy resin is basically selected as binder, conductive materials, fillers, solvents and additives are added to make epoxy antistatic floor paint.

(1)、环氧防静电地坪拥有环氧树脂地坪的一切优异性能,可快速排泄静电电荷、防静电效力持久;

(1) The epoxy anti-static floor has all the excellent properties of the epoxy resin floor, which can quickly excrete electrostatic charges and have a lasting anti-static effect.

表面电阻率达到106Ω-109Ω、地面电阻排泄符合国际GB6650-86A标准。

The surface resistivity reaches 106_-109_, and the surface resistance excretion meets the international GB6650-86A standard.

(2)、环氧防静电地坪整体无缝,能达到:防尘、坚韧耐磨、耐冲击、耐重压、

(2) The epoxy anti-static floor is seamless as a whole, which can achieve: dust-proof, tough and wear-resistant, impact-resistant, weight-resistant and pressure-resistant.

耐腐蚀、耐溶剂、平整亮丽、便于清理、维护,保养,且使用寿命长之目的。

Corrosion resistance, solvent resistance, smooth and bright, easy cleaning, maintenance, and long service life.

(3)、环氧防静电地坪可防止、清理静电、电磁波产生 、干扰破坏,抗静电效力持久。

(3) Epoxy anti-static floor can prevent and clean up static electricity, electromagnetic wave generation, interference and destruction, and the anti-static effect is lasting.

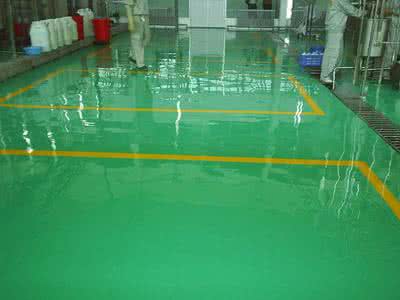

环氧地坪漆展示图

Epoxy Floor Paint Display

防静电地坪漆的施工方法:

Construction method of anti-static floor paint:

1. 基材整理:用研磨工具将素地之杂质研磨清除,并将混凝土表面粗糙化后,用工业吸尘器将灰尘完全清洁干净.

1. Material finishing: The ground impurities are removed by grinding tools, and the concrete surface is roughened. The dust is cleaned completely by industrial vacuum cleaner.

表面须平整,坚固且经充分干燥.

The surface should be smooth, firm and fully dried.

表面之油脂、泥土等须充分清除,素地不超过(含水率8%、湿度80%、温度高35°c低15°c)即可施作.

The grease and soil on the surface should be removed sufficiently, and the vegetable land can be applied without exceeding 8% moisture content, 80% humidity and 35_c high temperature and 15_c low temperature.

2. 底涂施做:将环氧底涂甲乙组分材料均匀搅拌,用滚筒十字法涂布在素地之上,约十个小时后,就可中涂施工。

2. Primer coating: Equilibrium mixing of epoxy primer A and B component materials, and coating on plain ground with roller cross method. After about ten hours, middle coating can be carried out.

3. 镘涂中涂层: 将环氧防静电自流平中涂材甲乙组分加80%的 石英粉均匀镘涂在底涂之上。

3. Intermediate coating in dysprosium coating: Apply 80% quartz powder to the base coating evenly by adding component A and B of epoxy anti-static self-leveling coating material.

4. 中涂研磨及整理:中涂硬化24小时后,检查中涂层表面,若发现中涂层有部分区域显露砂石粗糙面;

4. Grinding and finishing: After 24 hours hardening, inspect the surface of the middle coating, if it is found that some areas of the middle coating expose rough surface of sand and stone;

必须以环氧树脂批土进行修补批覆工作,否则影响面涂铺设之成败;

Epoxy resin batch soil must be used for repair and repair, otherwise the success or failure of surface coating will be affected.

待中涂硬化后,用研磨机械将表面石磨粗糙及清除杂质,并用工业用吸尘器将场地清洁干净.

After hardening, the surface is roughened and impurities are removed by grinding machine, and the site is cleaned by industrial vacuum cleaner.

5. 铜铂铺设:将铜箔按10M*10M见方贴,贴实地面并作接地

5. Copper and Platinum Laying: Copper foil is square pasted according to 10M*10M, adhered to the ground and grounded.

6. 导电底涂铺设:将导电底涂甲乙组分依比例均匀混合后, 用滚 筒均匀铺设于环氧砂浆层之上,二道间隔24小时。

6. Conductive primer laying: After uniformly mixing the A and B components in proportion, the conductive primer is evenly laid on the epoxy mortar layer with a drum, with a 24-hour interval between the two channels.

7. 面涂铺设:将防静电自流平面涂甲乙组分依比例均匀混合后, 用锯齿镘刀均匀铺设于导电底涂之上;

7. Surface coating: After uniformly mixing the components of A and B in proportion, the anti-static self-flow plane is evenly laid on the conductive primer with a saw-tooth trowel.

完成待48小时后,人员方可进入,七天后,重机械方可进入.

After 48 hours of completion, personnel can enter, and after seven days, heavy machinery can enter.

管理员

该内容暂无评论